It is almost impossible to list all the applications for linear actuators. You’ll find these motion devices anywhere adjusting, lifting, lowering, and sliding are required. However, they are different, and no one type is universal.

We have electric linear actuators and pneumatic, hydraulic, magnetic, and piezoelectric types. Each one has its pros and cons and best use cases. You must consider this when choosing a linear actuator for your application.

But there are many granular details you need to pay attention to as well. This and more we discuss next.

Factors to Consider When Selecting A Linear Actuator

If your application requires one, it needs the right one lest your project fails. The below factors are of the essence to ensure you choose the correct device:

● Load Capacity

Load capacity is a major determinant of the performance of your linear actuator. On the one hand, if it’s too much, the device may break down with use. On the other hand, if it’s too low, you won’t be maximising the capacity.

You’ll find information about load capacity in the manufacturer’s specifications. Note that it’s usually not a fixed number but a range. As a result, adjusting the capacity to fit different applications within its working range is viable.

● Speed

You can’t slip up on speed when picking a linear actuator. Some people do because they are relatively faster than rotary ones since they move in a straight line. However, some types are particular for high-speed tasks, while others are not.

A common speed max for linear actuators is 5 m/s. That’ll work for most applications, but if it’s explicitly a high-speed one, you need up to 10 m/s. In some cases, a 15 m/s linear actuator may be the only requisite.

● Stroke length

When talking about its speed, stroke length always finds its way into the discussion. Both factors go hand in hand. In particular, the stroke length affects the force of the actuator. So, for the device to travel longer and faster, it needs sufficient force.

They come in various stroke length sizes. In industrial applications, you’ll commonly find 50 to 250 mm ranges. However, some devices reach up to 1,000 mm and even 3,000 in demanding situations.

● Mounting options

Typically, how you mount a linear actuator into your machine or system influences its drive mechanism. The good news is that it’s not complex. Since these actuators move in a straight line, you can only mount them horizontally or vertically.

Horizontal mounting applications are relatively safer. The actuator moves from left to right (or right to left), so there’s no risk of a free fall should the machine lose power. With vertical mounting applications, the possibility of free fall is present. So, if you’re picking a vertical mount option, ensure it has built-in safety mechanisms.

● Environment

It’s essential to consider the environment where you employ a linear actuator. The last thing you want is to make the atmosphere uncomfortable for other people. In addition, you sure want the motion device to last for use.

Elements like temperature, humidity, dust, and others can affect the performance of a linear actuator. Therefore, you’ll need a more sturdy device if your environment is friendly to these harmful elements. Also, make sure the actuator isn’t ruining the surroundings.

The above is particularly important when using hydraulic ones. These types suffer leakages that can affect the environment. However, some are optimised to cause zero harm. Visit this website to find safe linear actuators for your applications.

● Maintenance

You may not like it, but your linear actuator will weaken with use. All devices do. However, you can help it last longer and lessen the likelihood of failure with moderate maintenance. For the most part, the only maintenance you need is lubrication.

The number of parts it features will tell how seamless or strenuous maintenance will be. Therefore, you should consider a device with fewer parts for easy upkeep. However, manufacturers make them with lubrication to last their lifespan. You should consider these types if you must use an actuator with many parts.

● Cost

Finally, give thought to the price you pay for the linear actuator. Suppose you will only use the machine or system a few times. Then, spending thousands on a motion device would be an overspending. However, for long-term use, you must commit sufficient funds to ensure you get a durable one.

Types of Linear Actuators to Choose From with Advantages and Disadvantages

Most often than not, you have to pick a linear actuator by its type. Check out the top ones below:

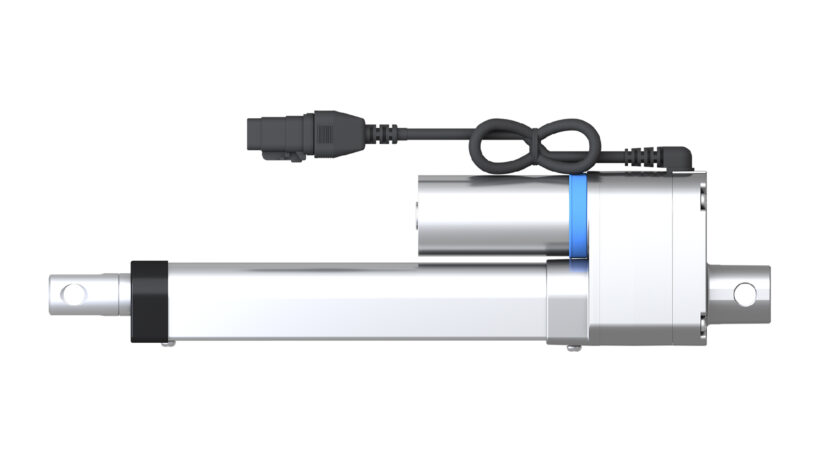

● Electric linear actuators

This type is common in robotics applications. They work by converting electricity into linear motion and usually use direct current.

| Advantages | Disadvantages |

| ● High precision

● Instant feedback ● Environmental friendly ● Easy to program |

● Expensive

● Motors can be large |

● Pneumatic linear actuators

Pneumatic ones use pressured gas or air. They’re common in industrial and aerospace applications.

| Advantages | Disadvantages |

| ● Affordable

● Safe to operate ● Environmental friendly ● Easy to use |

● Reduced accuracy

● Loud noise |

● Hydraulic linear actuators

Hydraulic oils and fluids power this linear actuator type. They’re common in heavy-load applications, thus, paramount in factory and engineering systems.

| Advantages | Disadvantages |

| ● High accuracy

● Constant force ● Easy to control ● Low noise |

● Expensive

● Not environmentally friendly |

● Piezoelectric linear actuators

These ones are similar to electric types since both feature an electric motor. However, piezoelectric actuators use voltage to work, and they’re common in tasks that require expanding.

| Advantages | Disadvantages |

| ● Power efficient

● High speed ● Allows small motions ● Works with voltage |

● High voltages may be unsafe

● Expensive |

● Mechanical linear actuators

They are one of the earliest types. They work without any power source, and their main function is converting rotary motion to linear.

| Advantages | Disadvantages |

| ● Affordable

● Requires no power source ● Ideal for repeated motion ● Self-contained |

● Has no automation and is only manually operated. |

Conclusion

Choosing the right linear actuator for your application requires careful consideration and evaluation of various factors. It is important to understand the specific needs and requirements of your project, as well as the differences in design, performance, and cost among available linear actuators. By following the tips we have shared you can make an informed decision and select the best one for your application.